Offshore Production Facilities

Many offshore production facilities suffer from piping failures and machine downtime due to excessive vibration.

These reliability/integrity issues have serious consequences such as gas or fluid release, potential fire/explosions, loss of life, environmental damage, equipment replacement/loss of use, and high maintenance costs.

Structural Vibration and Ways to Avoid it

Structural vibration occurs when dynamic forces generated by compressors, pumps, and engines cause the deck beams to vibrate. This vibration leads to piping failures, poor equipment reliability, and safety concerns. read more

Integrated Approach to Manage Vibration

This article outlines the recommended design approach to minimize piping, machinery, and structural vibration. Wood’s integrated engineering approach coordinates the different dynamic design issues into a complete solution, ensuring a successful project. read more

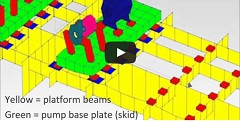

Structural Vibration and Dynamic Design Analysis

for FPSOs, Platforms, Elevated Structures

View MorePiping Vibration and Integrity Assessment

Piping vibration analysis per EI 2008 Guidelines for the avoidance of vibration-induced fatigue failure (AVIFF).

View MoreStructural Vibration Troubleshooting

Improving Integrity and Reliability on Offshore Production Platforms/FPSO

View MoreCondition Monitoring and Remote Vibration Analysis

for troubleshooting support or condition-based maintenance (CBM) applications

View MorePulsation & Mechanical Analysis: Reciprocating Compressor

Pulsation study, mechanical review and frequency avoidance analysis, forced response analysis (when required); per API 618, API 688 and GMRC High-Speed Compressor Guideline.

View MorePulsation & Mechanical Analysis: Reciprocating Pump

This analysis includes a pulsation study, a mechanical review, mechanical frequency avoidance analysis, and a forced response analysis (per API 674, API RP 688), if required.

View More