Products

Wedge Clamps

Clamps with superior vibration, installation and corrosion control

Wood’s line of anti-vibration wedge clamps offers superior pipe height adjustability at installation, excellent vibration control, can accommodate thermal growth and provide ease of corrosion inspection over the life of your facility.

Each model provides unique features to balance different requirements for your piping system designs.

Contact Wood’s anti-vibration products team for information on how to apply these products to your piping system today.

Contents [ hide ]

- 1 Anti-vibration wedge clamps

- WCL-1 Anti-vibration wedge clamp

- WCL-1-T Anti-vibration ThermaGlide axial-slide wedge clamp

- WCL-1-T-ST ThermaGlide axial- and lateral-slide anti-vibration wedge clamp

- 2 DamperX™ anti-vibration wedge clamps

- WDCL-1-HT DamperX

- WDCL-1-HT-T DamperX ThermaGlide axial-slide wedge clamp

- 3 Request a quote

- 4 Related information and services

1 Anti-vibration wedge clamps

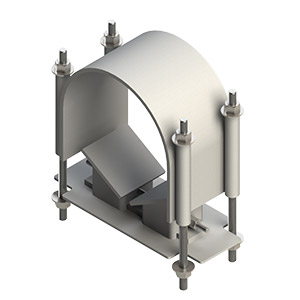

WCL-1 Anti-vibration wedge clamp

|

| WCL-1 Anti-vibration wedge clamp |

Applications:

- Hold-down clamps for piping in vibration service

- Variable height adjustment

- Easier inspections for piping corrosion

- Sizes from NPS 8” (DN 200) to NPS 42” (DN 1050)

Standard features:

- More bolt stretch than conventional pipe clamps, which reduces chance of vibration loosening

- Captive wedges and jigsaw shaped mounting plate remain under the pipe and will not slide off the support

- Customized finishes available: electroplated in nickel, zinc, or cadmium for sour gas, corrosive environments or offshore exposure

- Can be lined using PTFE to allow axial pipe movement due to thermal expansion

- Hardware and installation instructions included

- Carbon steel construction

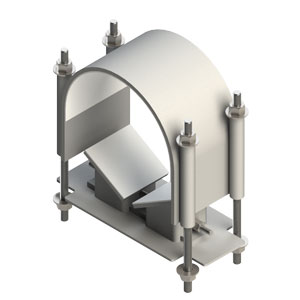

WCL-1-T Anti-vibration ThermaGlide axial-slide wedge clamp

|

| WCL-1-T Anti-vibration wedge clamp for low-friction applications (axial slide) |

Applications:

- Hold-down clamps for piping in vibration with thermal growth requirements

- Where axial piping movement is required

- No metal-to-metal contact between pipe and clamp

- Easier piping corrosion inspections

- Variable height adjustment

- Sizes from NPS 8” (DN 200) to NPS 42” (DN 1050)

Standard features:

- More bolt stretch than conventional pipe clamps, which reduces chance of vibration loosening

- Low-friction PTFE lining clamp and wedge supports ensuring no metal-to-metal contact with pipe

- Allows axial pipe movement due to thermal expansion

- Captive wedges and jigsaw-shaped mounting plate remain under the pipe and will not slide off the support

- Customized finishes available: electroplated in nickel, zinc, or cadmium for sour gas, corrosive environments or offshore exposure

- Hardware and installation instructions included

- Carbon steel construction

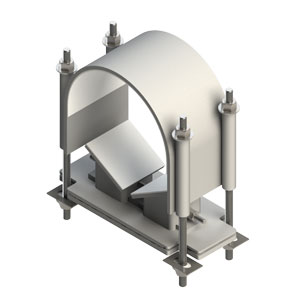

WCL-1-T-ST ThermaGlide axial- and lateral-slide anti-vibration wedge clamp

|

| WCL-1-T-ST Anti-vibration wedge clamp for low-friction applications (axial AND lateral slide) |

Applications

- Hold-down clamps for piping with vibration and thermal-growth requirements

- Where axial and lateral piping movement is required

- Variable height adjustment

- Easier piping corrosion inspections

- Sizes from NPS 8” (DN 200) to NPS 42” (DN 1050)

Standard features:

- More bolt stretch than conventional pipe clamps, which reduces the chance of vibration loosening

- Low-friction PTFE lining clamp and wedge supports ensuring no metal-to-metal contact with the pipe

- Allows axial pipe movement due to thermal expansion

- Allows lateral pipe movement due to thermal expansion with patent-pending ST hardware and PTFE sliding plate provided

- Captive wedges, jigsaw-shaped mounting plate and sliding pad remain under the pipe and will not slide off the support

- Customized finishes available: hot-dip galvanizing, electroplating in nickel, zinc, or cadmium for sour gas, corrosive environments, or offshore exposure

- Hardware and installation instructions included

- Carbon steel construction

2 DamperX™ anti-vibration wedge clamps

WDCL-1-HT DamperX

|

| WDCL-1-HT DamperX™ wedge clamp |

Applications:

- Hold-down clamps with damping for superior resonant vibration control with DamperX™

- Variable height adjustment

- No metal-to-metal contact between pipe and clamp

- Easier inspections for piping corrosion

- Sizes from NPS 8” (DN 200) to NPS 42” (DN 1050)

- Temperatures from 15°F to 400°F (-9°C to 204°C)

Standard features:

- Same features as the standard anti-vibration wedge clamp, but with additional resonant vibration damping due to liner and wear pad made of viscoelastic material (DamperX™ Black)

- Reduces vibration 40% to 90% compared to regular clamps

- Captive wedges and jigsaw-shaped mounting plate remain under the pipe and will not slide off the support

- Vibration locking washers to further prevent vibratory loosening

WDCL-1-HT-T DamperX ThermaGlide axial-slide wedge clamp

|

| WDCL-1-HT-T DamperX™ wedge clamp for low-friction applications |

Applications:

- Hold-down clamps for superior resonant vibration control with DamperX™

- Where axial piping movement is required

- Variable height adjustment

- No metal-to-metal contact between pipe and clamp

- Easier inspections for piping corrosion

- Sizes from NPS 8” (DN 200) to NPS 42” (DN 1050)

- Temperatures from 15°F to 400°F (-9°C to 204°C)

Standard features:

- Same features as the Standard Anti-Vibration Wedge Clamp, but with additional resonant vibration damping due to liner and wear pad made of viscoelastic material (Dampion™ Black)

- Reduces vibration 40% to 90% compared to regular clamps

- Low-friction PTFE lining clamp and wedge supports ensuring no metal-to-metal contact with pipe

- Allows axial pipe movement due to thermal expansion

- Captive wedges, jigsaw-shaped wear pad remain under the pipe and will not slide off the support

- Vibration locking washers to further prevent vibratory loosening

3 Request a quote

Contact Wood’s anti-vibration products team for more information, detailed drawings, pricing and application support.

4 Related information and services

Webinar: Pipe stress and vibration modeling techniques

Article: Hydrocarbon Engineering (August 2016) (PDF)

Anti-vibration clamps for general purposes

Pipe Support Stiffness (2014 GMRC research overview)

IMPROVED THERMAL PIPING ANALYSIS FOR RECIPROCATING COMPRESSOR PIPING SYSTEMS, GMC PAPER 2012 (PDF)