Products

DamperX™ Technology

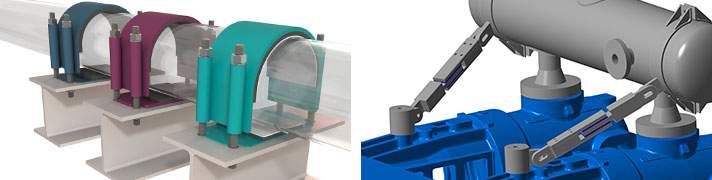

Vibration-damping pipe clamps, braces and supports

| DamperX™ Clamp |

DamperX™ Brace |

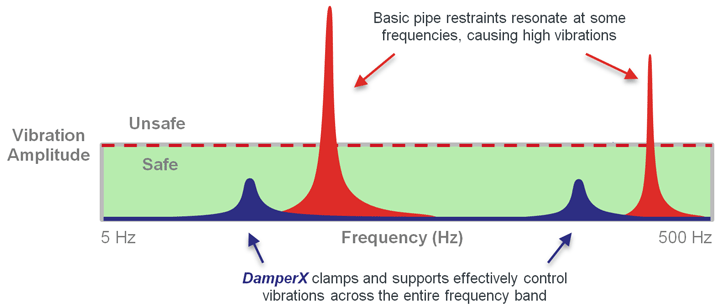

Vibration is a leading cause of piping fatigue failures and can cause safety risks, environmental damage and downtime. Traditional pipe clamps often do not produce a satisfactory solution for vibratory loads. The vibration can be shifted elsewhere on the structure, or the clamp is not effective at all operating speeds or conditions.

DamperX™ is Wood’s line of products that addresses these issues. Building on extensive research, DamperX products have a proven track record of significantly reducing vibration compared to standard steel and other lined clamps and supports.

Contents [ hide ]

How damping reduces vibration and failure risks

Our vibration engineers have applied this technology to industrial applications involving piping, compressors, pumps and related equipment. This new solution provides a cost-effective approach to absorb vibration energy and reduce stress, thereby preventing fatigue failures.

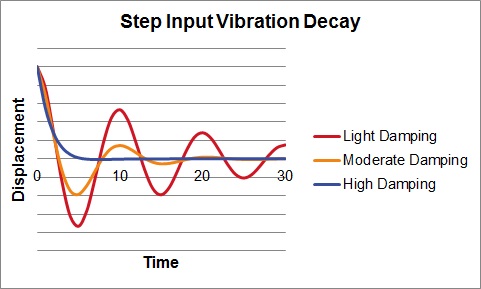

Welded piping systems typically have very low damping. When vibration forces occur, these piping systems become highly responsive when resonant, leading to amplified vibrations and fatigue failures. With low-damped systems, the vibration ringdown time after the initial event can be severely long.

Damping is a proven solution to control vibration and is used extensively in the automotive and aerospace industries (think of the shocks in your car).

A DamperX vibration-damping pipe clamp or brace adds significant damping to the system. The figure (right) illustrates how damping absorbs vibration energy. An undamped system (red line) will continue to ring. Adding damping absorbs the vibration energy and reduces stress on the piping system (orange and blue lines).

A DamperX vibration-damping pipe clamp or brace adds significant damping to the system. The figure (right) illustrates how damping absorbs vibration energy. An undamped system (red line) will continue to ring. Adding damping absorbs the vibration energy and reduces stress on the piping system (orange and blue lines).

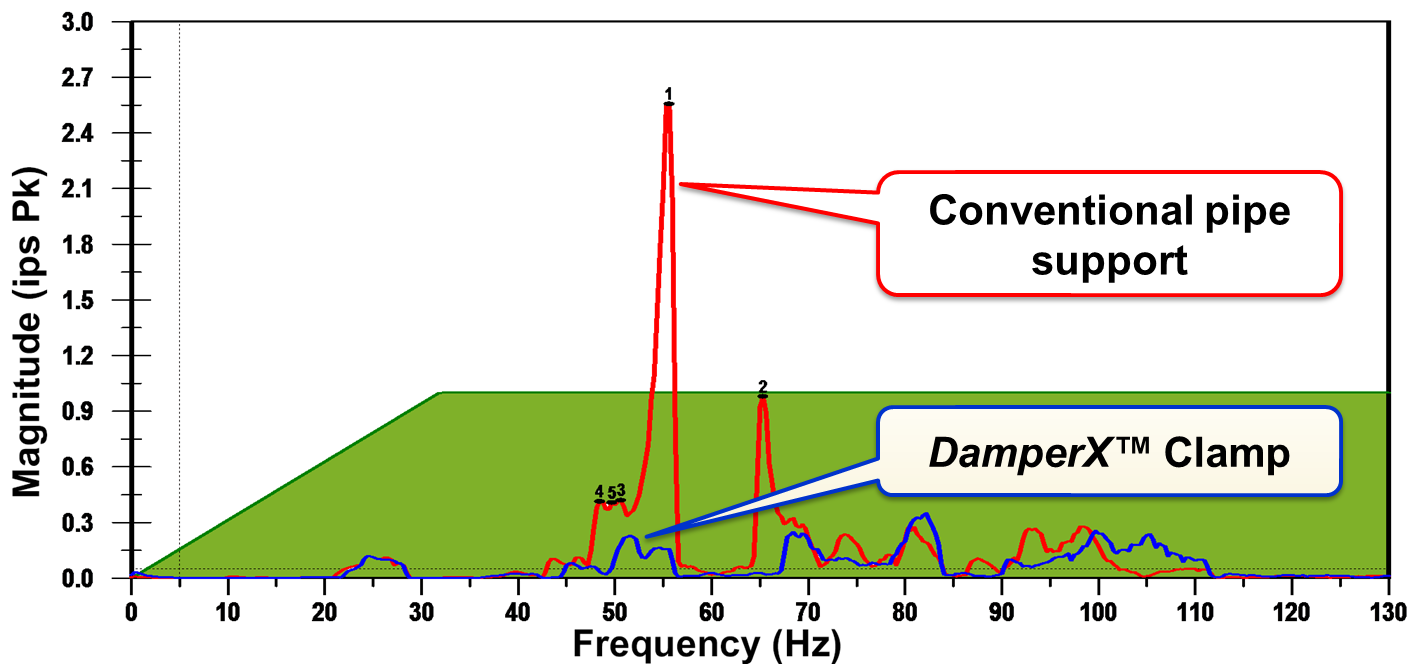

Development testing revealed that many commercially available clamp liners actually increase vibration amplitude, due to a decrease in stiffness. The viscoelastic material used in Wood’s DamperX products provides a unique combination of stiffness and damping, resulting in a significant reduction of overall piping vibration.

Another advantage of damping is the ability to absorb energy across a wide frequency range (up to 500 Hz). Vibration will occur at many frequencies. A traditional steel brace will be resonant at specific frequencies (eg, at its natural frequency) and result in excessive vibration. Damping has been proven to absorb energy across all frequencies.

Applications

DamperX products are uniquely designed for:

|

Facilities

|

Piping, vessels and machinery systems

|

DamperX™ products

See this one-pager for an overview of our vibration-damping products

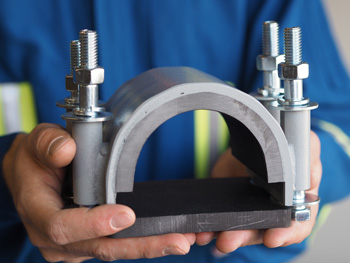

1. Clamps

Wood’s DamperX vibration-damping pipe clamps have a damping material liner and require the provision for a damping material pad under the piping (dimensioned installation drawings are available on request). The clamps are intended for suction piping or piping downstream of after-coolers, and are effective at temperatures from 1°F to 400°F (-17°C to 204°C).

Wood’s DamperX vibration-damping pipe clamps have a damping material liner and require the provision for a damping material pad under the piping (dimensioned installation drawings are available on request). The clamps are intended for suction piping or piping downstream of after-coolers, and are effective at temperatures from 1°F to 400°F (-17°C to 204°C).

Advantages

- Superior vibration reduction compared to alternative pipe clamps that only add stiffness

- Reduces likelihood of moving the vibration problem elsewhere

Cost-effective and reliable method to control resonant and non-resonant vibration

Cost-effective and reliable method to control resonant and non-resonant vibration- Ideal for high-speed and variable-speed applications

- Field data has shown that DamperX clamps reduce vibration 40 to 90% when compared to conventional steel clamps

- Engineered solution based on FEA and damping modeling techniques

- Customized design for OEM, packagers and customer-defined requirements

- With a lower coefficient of friction than conventional clamps (µ= 0.15 to 0.25), DamperX clamps are designed to permit axial pipe movement due to thermal expansion

Email us today or call +1 403 245 5666 to order or get more information on price, delivery, and installation.

Brochure (PDF)

|

| There are many examples where traditional pipe clamps are unable to control machinery and vibratory loads |

Wedge clamps

Learn more about our line of anti-vibration wedge clamps

2. Braces

Wood's engineers have developed a variety of DamperX brace models designed for main process piping and vessels. As opposed to adding only stiffness to a vibrating system, the DamperX support contains a viscoelastic element which absorbs the vibration of the component instead of transmitting it to the supporting structure.

Wood's engineers have developed a variety of DamperX brace models designed for main process piping and vessels. As opposed to adding only stiffness to a vibrating system, the DamperX support contains a viscoelastic element which absorbs the vibration of the component instead of transmitting it to the supporting structure.

The DamperX brace must be rigidly attached in the correct location and orientation for effective reduction of vibration.

Aluminum, stainless steel, and carbon steel versions are available. The unit can be configured for different lengths and connections. Band clamp and skid lugs hardware is provided for retrofit applications. Installation instructions are provided in both electronic and hard-copy versions.

Advantages

- Superior vibration reduction compared to alternative supports that only add stiffness

- Reduces likelihood of moving the vibration problem elsewhere

- Cost-effective and reliable method to control resonant and non-resonant vibration

- Works across a wide speed range thus ideal for variable speed machines

- Ease of installation with the ability to install while equipment running and at operating temperatures

- Higher confidence that desired vibration reduction will be achieved compared with traditional brace

- Engineered solution based on unique FEA and damping modeling techniques

- Much smaller and less intrusive than traditional braces for the equivalent vibration reduction

- Customized design for OEMs, packagers, and customer-defined requirements

Email us today or call +1 403 245 5666 to order or get more information on price, delivery, and installation.

3. Fins (gusset plates)

DamperX fins dampen out excessive vibrations on small-bore attachments.

The fins (or "gussets") come custom-cut for your application, based on some photos and basic dimensions, and can typically be installed within 20 minutes – no welding required.

4. Cylinder head-end supports

The cylinder support is currently in testing. Please contact us for demo applications.

Advantages

- The viscoelastic material support reduces vibration at all frequencies. Conventional all steel supports often simply move vibration problems to a higher frequency.

- Ease of fit-up and installation. Improper alignment of a rigid, all-steel supports can create misalignment within the compressor. The DamperX support eliminates installation problems; its material is relatively pliable and the design allows for easy alignment.

- Engineered to meet the optimal stiffness and damping requirements of the specific compressor application, using unique FEA and damping modeling techniques.

Online training

Part 1: how to model pipe supports, vibration and piping stress more accurately

Watch the replay

Part 2: how to select the right pipe clamp to control vibration and allow thermal growth

Part 2: how to select the right pipe clamp to control vibration and allow thermal growth

Watch the replay

Part 3: how to quantify performance of pipe supports for vibration service

Part 3: how to quantify performance of pipe supports for vibration service

Watch the replay

Technical support

Owners rely on Wood’s experts to mitigate vibration, dynamics, and stress issues.

Our specialist will:

- Provide troubleshooting and vibration assessments at your site

- Identify the best vibration solution

- Verify and document that the modifications are successful and meet your integrity and reliability specifications

How to order

Email our products team or call +1 403 245 5666 to order or get more information on price, delivery, and installation.

Testimonials

"I have reviewed Wood’s pipe vibration products [...]. From a piping engineering perspective, Wood's pipe clamps are not just a clamp, but are an engineered product backed with design data that often not available from other manufacturers"

– Piping engineer, Operator, North America

"We are very pleased with the end product we received. The clamp effectively reduced the vibration to an acceptable level, which has mitigated a huge safety concern that has been bearing over the unit for several months."

– Reliability engineer, Operator, North America

Video: damping liner test

Related information and services

- Anti-Vibration Clamps, incl. DamperX™ and ThermaGlide™

- DamperX fins for small-bore attachments

- Brochure: DamperX clamp

- Brochure: CL Anti-vibration Clamps for General Purposes

- Technical report: Effects of various clamp liner materials on piping system vibration

- Free webinar: How to select the right pipe clamp to control vibration and allow thermal growth

- Free webinar: New piping stress modeling techniques for more accurate designs

- Article: Hydrocarbon Engineering (August 2016) (PDF)

- Anti-vibration wedge clamps

- PIPE STRESS ANALYSIS

- Pipe Support Stiffness (2014 GMRC research overview)

- A RECOMMENDED APPROACH TO PIPING FLEXIBILITY STUDIES TO AVOID COMPRESSOR SYSTEM INTEGRITY RISK, GMRC 2011 (PDF)

- IMPROVED THERMAL PIPING ANALYSIS FOR RECIPROCATING COMPRESSOR PIPING SYSTEMS, GMC PAPER 2012 (PDF)

- VIBRATION ABSORBErs

-

DamperX™ Technology

{content}