Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Data acquisition for remote monitoring and troubleshooting – ask the expert

Q&A from our webinar "Insight out – data acquisition for remote monitoring and troubleshooting"

By Ramin Rahnama, Colin McIlwraith and Dominic Cummins

Watch the replay Learn more or get a quote

The answers below were given in the context of the webinar and do not address all aspects of the issues discussed.

For more comprehensive information or application support, we strongly encourage you to contact our experts directly.

Contents [ hide ]

1 Installation

|

|

If required, Veridian iDAC can be configured intrinsically safe |

Can you install Veridian iDAC and its sensors while the process is online?

It depends on the sensor type, but yes, the vast majority of sensor types can be installed while equipment is online.

2 Applications

Have you done baseline studies to gather data at the start-up of new rotating equipment?

Yes, we often undertake baseline readings on new equipment. Often these are carried out with staffed surveys using multi-channel equipment and a combination of portable equipment, rather than Veridian iDAC.

For baseline surveys, it’s often required to move sensors to effectively capture all locations. However, in the event that a staffed survey is not practicable, then Veridian iDAC can be used.

Are you able to monitor torsional vibration of rotating equipment?

Yes, we can measure torsional vibration. We have a number of specialized sensors that can measure torsional or shaft vibration and stress.

Additionally, Veridian iDAC can measure more common machinery vibration such as bearing vibration, casing vibration, etc. It can be used for the purpose of fault-finding or even routine condition monitoring.

|

|

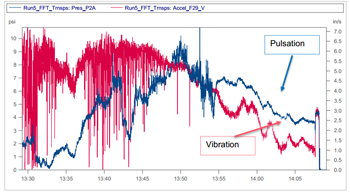

The root cause of this problem was related to excessive pulsation in the discharge piping of a compressor, resulting in fatigue failures of small-bore piping |

When should a monitoring system be installed? Only when problems occur or from the design?

Depending on the type of equipment and the criticality of the system, monitoring systems are often installed at the design stage.

However, in later assets, where a monitoring system has not been implemented or doesn’t capture the required data, Veridian iDAC can be a highly effective solution.

The modular nature of the system allows for a simple installation, which enables operators to monitor and maintain their equipment throughout its life cycle or during a troubleshooting exercise.

Can subsea control systems data be imported for analysis?

In simple terms yes, we can measure anything with a voltage when it comes to sensors, so we have unlimited options there.

As for the control system data, we can read it via can bus or, if it’s an analog output, we can easily read that too. Outputs from systems like PI can also be linked and analyzed.

Is Veridian always a bespoke solution that has to be configured for each application, or can you invest in a portable system that you can move between sites?

Veridian iDAC is configured to solve a specific problem, and typically it’s not used as a portable system. However, our engineers do utilize a number of portable systems that can be moved between sites. Please contacts us to discuss solutions for your application.

|

|

In this application, sensors were housed in the small and unobtrusive box measuring 32 channels in a Zone 2 area |

What was the solution in case study 2 in the webinar?

We measured various operating conditions over the course of two weeks, allowing us two capture all vibration envelopes.

Once captured, we input our readings into an operating deflection shape (ODS) model, which allows us to graphically represent the movement of the pipe. Additionally, we compared all of our readings against the Energy Institute guidelines, and where they were breached, we installed supports which restrained movement in the direction identified during the ODS modelling.

As part of the validation program, we recaptured vibration and dynamic stress readings using Veridian iDAC to ensure that the clamps were in fact effective. This allowed the operator to have complete confidence that there would be no vibration risks for any of their operating conditions.

As a result of the installation of the iDAC system, the operator now plans to carry out the same tests at a number of their other pumping stations for the airport.

3 Data, connectivity and integration

|

|

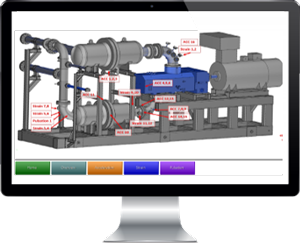

Dashboard showing measurement areas on a machine and its suction and discharge sides |

Does data need to go in the cloud or is there an on-premise solution?

If an on-premise solution is preferred, data can be stored locally on external hard drives or sent to a central location within the site.

What can be done for remote locations without internet access?

For locations without existing internet service, we have a number of different solutions ranging from the installation of a 4G connection to installing a satellite broadband connection.

We can also install a standalone Wi-Fi network which can piggyback off existing Wi-Fi networks elsewhere on the site to allow for cloud storage and remote access.

Does the system only monitor and analyze its own sensors’ data or can it also integrate PI data?

Veridian iDAC can utilize both its own data and PI data; it can directly receive outputs from PI and can provide PI with inputs.

We have developed a low-cost wireless remote monitoring system for machinery at our sites, can you work alongside this or integrate with it?

In short, yes we can work alongside a vast number of technologies or hardware, and we’re always interested in teaming up with companies offering new technologies.

|

|

Veridian iDAC can be connected to your control room and other interfaces |

In general, Is iDAC friendly to work with other software and interfaces?

Yes, Veridian iDAC can connect to a vast range of interfaces.

4 Power supply

What kind of system for energy harvesting is used, eg, for fatigue monitoring using ASME or PD5500?

We can implement a number of different energy harvesting technologies where power cannot be provided such as at a remote section of pipe.

Veridian iDAC can utilize a combination of solar panels and a small-scale wind turbine to harvest enough energy to power the system.

5 Sensor selection

There are many sensor options on the market. How do you choose which Wi-Fi sensor type and manufacturer to use?

Typically we base our sensor choice firstly on the environment, ie, is it a hazardous area/non-hazardous area, is it a high-temperature area, etc.

After that, we look at what we want to measure, ie, it needs to have the right range so it’s not overloaded and the right frequency response and resolution.

When it comes to wireless sensors, there are added complications in the fact that they often have reduced battery life and their sample rates are not the same as traditional sensors meaning they can only do a number of spot measurements a day or per hour compared to continuous high-resolution measurements from a traditional wired sensor.

It’s important to understand wireless sensors limitations and what you’re trying to achieve with them. They’re not always practicable for all measurement types, although sensor suppliers will often beg to differ.

Look out for our webinar on wireless sensors later this year for more detailed coverage of this subject.

Related Pages

Veridian iDAC • Webinar: Insight out • Field engineering and troubleshooting • Rotating equipment reliability • Webinar: (Digital) reliability = profitability •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now