Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Small-bore piping connections – ask the expert

Q&A from our webinar on small-bore connection integrity "Testing the limits"

By Chris Harper, PEng, Principal Consultant

The answers below were given in the context of the webinar and do not address all aspects of the issues discussed.

For more comprehensive information or application support, we strongly encourage you to contact the expert directly.

Contents [ hide ]

- 1 Causes of vibration

- 2 Evaluation and modelling

- - Guidelines, criteria and LOF

- - Methods

- - Resonance and natural frequency

- - Veridian

- 3 Inspection and measurement

- 4 Mitigation methods

- - AIV/FIV issues

- - Equipment types; tubing, gussets, flanges

- - Supports, braces and damping

- - Resonance/MNF

- 5 Strategy and process

- 6 Other

- 7 More webinars and online calculators

1 Causes of vibration

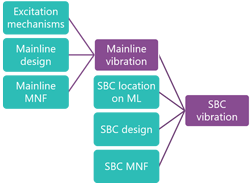

|

| Root causes of small-bore vibration |

|

| Example of dead leg branch vortices |

What is the relation between fatigue failure and natural frequency?

Most fatigue failures are caused by resonance. Therefore, a lower natural frequency typically results in a longer fatigue life (for a given stress range). However, in many cases, excitation mechanisms present in piping systems have a higher amplitude at lower frequencies, so if the piping and SBCs have lower natural frequencies, they will tend to have higher vibrations.

If something will fail after a million cycles, if it vibrates at a lower frequency (ie, lower cycles per second), then it will take longer to reach a million cycles and fail, ie, a longer fatigue life.

However, the amplitude of forces present in piping systems isn’t constant over the frequency range, and the forces tend to be higher at lower frequencies. Therefore, even though the fatigue life might be longer at lower frequencies, the forces are higher, which will tend to lower the fatigue life.

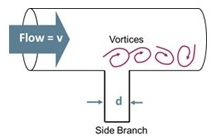

With no rotating equipment nearby, it appears that flow-induced vibration is causing instrument and small-bore failures, is FIV the correct term?

There are several phenomena that are described as FIV or flow-induced vibration. Vibration/pulsation caused by turbulent flow is sometimes called FIT (flow-induced turbulence). Vibrations/pulsations caused by flow past dead legs is also called FIV or FIP (flow-induced pulsations). Low-frequency vibrations in systems without machinery (especially reciprocating machinery) are typically flow-induced.

In liquid systems, do you believe cavitation or flow problems, such water hammer, are the cause for most of the vibration problems?

In my opinion, most vibration problems in liquid systems are due to flow-induced turbulence and pressure-reducing devices like control valves. Cavitation and transients can be a problem but are usually spotted early in design.

2 Evaluation and modelling

- Guidelines, criteria and LOF

What overall vibration limit can we use for small-bore piping?

A good rule of thumb is 1 in/s 0-pk either spectrum or overall.

How can you identify the vibration-causing lines during engineering?

Generally, we (stress engineers) don’t include small-bore lines in the critical list and don’t do any analysis. Stress engineers often decide this based on experience, and we may end up with different opinions to apply or not apply gussets or different support types on SBCs.

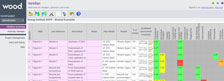

|

| Veridian evaluates fatigue failure risks based on the EI AVIFF standard |

The Energy Institute guidance can be used to estimate the likelihood of failure (LOF) on main lines.

Our free online tool Veridian screens piping based on EI criteria. SBCs on the high LOF lines can then be investigated and potentially braced. Please see our webinar “Stress relief” for more information on how to consider vibration in pipe stress analysis.

Are these guidelines applicable to small-bore tubing as opposed to small-bore piping?

The Energy Institute provides a tubing standard that includes guidance for vibration performance.

Are the VDI 3842 or EI guideline applicable to SBF which has gussets or bracing?

Any other way to quickly asses potential fatigue at such points?

Yes, these guidelines apply and can indicate if the brace or gusset is effective. However, vibrations that are above the guideline are less likely to result in a fatigue failure at the connection protected by the gusset/brace, but the failure point may have moved to another area.

Whenever there is a new design on existing systems, what length on the existing systems should I consider avoiding a high LOF (likelihood of failure)? Would it be enough to consider the existing one or two supports upward and downward of the tie-in point?

I would recommend evaluating the LOF on the mainlines in the scope of the tie-in. Generally, one or two supports would be reasonable to consider. An exception might be in reciprocating compressor/pump lines, where pulsations can travel significant distances.

Would you resort to an infinite life design (based on BS 7608 endurance limits) OR is it possible to do a finite life design. The question is – would it be easy to obtain the fatigue loading spectrum?

To do a finite life design, we would either need strain gauge measurements near the weld or vibration measurements and an FEA model. If these measurements are representative, then we can calculate fatigue life.

The challenge is taking measurements on upset conditions, and/or understanding their intermittency. It is also possible to do this type of assessment at the design stage. An infinite life can be assumed in many cases providing the maximum dynamic stress range remains below the constant amplitude fatigue limit; in some critical cases (eg, subsea) a full fatigue life assessment is often done even if the maximum stress is below the CAFL, using a 2 slope S-N approach as per (for example) BS7608.

VDI 3842 – Seems that >10mm/s RMS is the high-risk threshold. What does 'high risk' mean? Will this fail in the next 1 month? 6 months? 12 months? 3 years?

Upset vibrations can lead to fatigue failure over months or years, depending on their intermittency.

What are the criteria to accept pulsation pressure in the reciprocating compressor?

This is detailed in the API 618 pulsation guidelines.

Is there a safety factor you use when evaluating connections with a higher stress concentration factor, such as threaded connections, against either the VDI or EI curves?

Given the curves are fairly conservative, we do not use a correction factor for threaded connections. We do use a factor when doing FEA on threaded connections.

Do you recommend velocity RMS or velocity Peak for vibration evaluation?

Is it acceptable to evaluate tubing vibration against VDI or EI guideline?

In general, using RMS is recommended for vibration velocity readings, as most criteria are based on RMS values. Note: strain measurements would normally be reviewed in the time domain and the maximum pk-pk value taken because most fatigue guidelines use stress ranges, not RMS.

Is there a recommended D/t for the main pipe?

The D/t ratio is important for several excitation mechanisms (eg, AIV and FIT) but the 'optimum' D/t ratio will vary for a given pipe size depending on the level of excitation. The Energy Institute methodology is more detailed than the Eisinger method.

What standard is the criterion 4.8RS/60 etc to determine HZ based on?

What standard is the provided distance between the SBC and the source from (eg, pump and control valve)?

These are based on the GMRC/PRCI SBC standard GMRC “Design Guideline for Small Diameter Branch Connections [paid].

In the nuclear industry, anything above 33 Hz is considered rigid. Is there an equivalent or similar criterion outside of nuclear application?

In the Energy Institute method, piping natural frequencies >15 Hz are considered "stiff."

- Methods

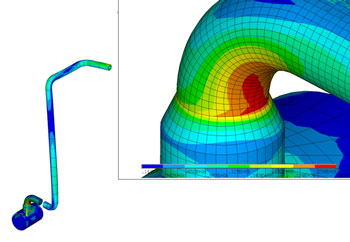

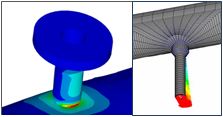

|

|

Finite element analysis (FEA) is used to calculate stress and confirm acceptance (or failure) of small-bore piping design |

How accurate is the FEA analysis as compared to what happens on the field?

SBCs are relatively easy to model, so the matching is within +/-10%. The most challenging part is getting the correct mass of components like valves because they are a larger percentage of the total SBC mass.

Is there a software, where you enter the diameter and the frequency with amplitude, and it gives you the danger level, or do you just put the formula in a spreadsheet

Most people just create a spreadsheet.

Does Wood have a vibration measurement result to stress conversion table/software/procedure/methodology?

The risk associated with vibration is difficult to quantify, unlike stress; the relationship between vibration and stress (whilst generally linear) will depend on the geometry of the SBC. We either use direct strain measurement or use vibration velocity in conjunction with an FEA model to obtain the dynamic stress.

Why do you recommend using velocity instead of displacement pk-pk when quantifying vibration in piping?

Velocity is more closely related to stress than displacement in piping – this is because, for a dynamic system, vibration velocity relates to strain energy. Failure on SBCs is mainly caused by relative motion between the SBC and the mainline, either by vibration or static deflection.

|

Dynamic stress analysis of an ROV intervention line |

How can we make a comparison of sweepolet and other measures of SBC mathematically?

Comparisons can be made mathematically using, for example, FEA.

Can subsea pump piping vibrations be avoided by analysing using ANSYS and MATLAB?

For subsea systems, the first point of reference should be the Energy Institute subsea guidelines

- Resonance and natural frequency

Does the specified minimum MNF have to be for the isolated small-bore connection or for the whole connected pipeline?

As long as the MNF of the SBC and the MNF of the main line are far enough away from each other, they can be treated as separate for the purpose of modelling.

In an SBC FEA analysis, from vibration measurements, how can we get back to the excitation forces?

It is very difficult to back-calculate forces from vibration. In can be done with an accurate FEA model that has been tuned from field measurements. It is much easier to measure pulsations in the piping system to estimate excitation forces.

In a modal analysis in CAESAR II, what frequency is considered acceptable to avoid vibration?

The mainline MNFs in the presentation can be used to compare to the MNFs calculated in Caesar II.

- Veridian

How can I access Veridian online?

You can access Veridian here on our website

Have you included Lockhart-Martinelli parameter in Veridian or this is being included in next revision of Energy Institute Guideline?

The multiphase screening assessment will be updated in the next revision of the EI document to consider the variation of dynamic force with liquid fraction. This will also be included in Veridian.

Veridian – some evaluation of failure is subjective. How does Wood propose to ensure that a subjective evaluation is applied consistently?

Veridian and the Energy Institute method strive to be as objective as possible; the SBC parameters used in Veridian (and as provided in the EI Guidelines) attempt to remove as much of the subjectivity associated with the SBC assessment as possible.

- Other

Any recommendations for Ductile iron cement lined sewage pipes

Non-metallic vibrations can be difficult to analyze due to their unique fatigue characteristics. Using the VDI 3842 vibration curves is a reasonable starting point.

3 Inspection and measurement

How can inspection mitigate vibration risks? Does it mitigate risks by monitoring/installing vibration probes? Since API 581 does not specify the level of inspection effectiveness for mechanical fatigue and/or VIF?

Identifying potential vibration hotspots and conditions can help identify where suitable vibration or strain measurements should be performed. These measurements can then be used to help determine the fatigue damage that is being accrued. The main link with RBI is that the vibration screening uses the same input data as an RBI assessment (piping and process information) and so a vibration assessment is very straightforward to do 'off the back' of an RBI study.

How to convert field vibration data from time domain to frequency domain in a program like Caesar? Or do we need to use FEA (ANSYS/Abaqus) instead of Caesar?

Time-domain data can be converted into frequency domain using software that does a DFT (Discrete Fourier Transform) on the data. Even Excel can perform this calculation.

|

| Field audit of small-bore connections |

What simple tools can be used to evaluate SBC vibration in the field, at a high level, to identify areas of concern? Are there transducers that can be attached to say iPhone to do a first level of evaluation?

The accelerometers in smartphones are sufficient to take simple readings of low-frequency vibrations and can be used as a screening. There are several apps available that can help with this.

Can we use bump test measurement to predict high vibration? How effective is it?

Bump tests are not very effective to predict if a particular connection will experience high vibrations, although it can be useful to check if a natural frequency of the SBC will coincide with a discrete frequency excitation (eg, machine running speed).

What are the requirements/methods for doing a field vibration measurement for SBC? do I need to be a certified vibration analyst before undertaking a field vibration measurement?

It is a specialized skill that takes some experience. However, in theory, measuring vibration on the SBC and mainline, taking the difference, and plotting it vs a guideline is not too difficult. There are no certification courses, as far as I know.

Can you provide a bit more explanation on your statement that once you have seen an SBC in the field, you can remove some of the conservatism?

Natural frequencies predicted from FEA have uncertainties that should be accounted for (typically assumed to be +/-10%). Natural frequencies measured in the field do not have that uncertainty, and only resonance-avoidance is required (typically another +/-10%).

|

Reciprocating compressor discharge bottle drain vibration made visible by a motion amplification camera |

4 Mitigation methods

- AIV/FIV issues

I have an AIV created by 12" discharging vertically into a 34" pipe. What are some mitigation options?

See the paper AIV and FIV in Pipelines, Plants, and Facilities (PDF) for a discussion on AIV mitigation options.

A screening assessment following the Energy Institute approach should be done first to give an estimate of the potential risk. If a potential issue is confirmed, then a more detailed analysis can be performed using FEA techniques. Generally, the weak points for AIV are welded (non-axisymmetric) discontinues on the parent pipe. Increasing wall thickness locally can reduce the susceptibility to AIV excitation.

For AIV/FIV lines do we need to apply acoustic insulation on trunnion supports? For other secondary supports, we can isolate systems by vibration-absorbing pads.

Acoustic insulation generally only provides a benefit in terms of external noise levels – it does little (if anything) to mitigate the integrity threat associated with vibration.

- Equipment types; tubing, gussets, flanges

|

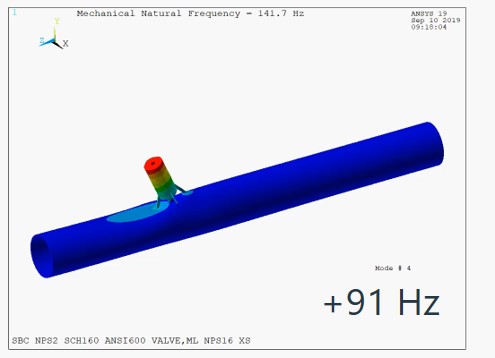

| Adding gussets increased the MNF by 91 Hz in this example of parallel mode SBC vibration |

|

| Four-gusset designs with welding pads are best for vibrating systems |

When gussets are welded on the flange, how is the stress analysis done? Flanges are meant to seal and not carry loads; the bolts were designed for sealing only.

When gussets are added to increase the natural frequency, they shouldn't see significant loads, as long as vibration is avoided due to the gussets. However, there may be static loads that impact the design. Perhaps a tool such as NozzlePro could be used.

Would adding gussets increase the rate of corrosion at that point?

Provided the correct material is used, galvanic corrosion shouldn't be an issue.

Is tubing better or worse than flex hose for vibration?

There is some concern of fretting when flex hose vibrates, however, flex hose tends to dampen out vibration. I would tend to recommend well-supported tubing.

What do you think of using tubing instead of pipe?

Tubing is useful to isolation vibrations of the mainline from remote mounted sensors. However, care must be taken that the tubing does not become a vibration issue.

Why don't all compressor package manufacturers choose flanged connections as opposed to threaded connections?

While threaded connections have risks associated with failure at the threads and leaks, flanged connections are longer and heavier. In some cases, threaded connections can work.

Is it important to always use higher-schedule nipples (eg, 160 Sch) coming off the mainline to instruments like PG, TG, etc?

Yes, we recommend using a higher schedule.

Can you provide some kind of cost associated with these monoflange connections schematics?

Monoflanges and studding outlets can be more expensive than other components.

Do you recommend tubing and remote instrumentations instead of piping?

Running tubing to remote mounted sensors can increase labour costs.

- Supports, braces and damping

Due to the high cost bracing can have, at what level of the severity (medium to high) should we recommend bracing SBCs? Or would you perform further analysis before making such a recommendation?

If the vibrations are above the VDI 3842 Correction Line but below the Danger Line, further investigation can be done before bracing is recommended. If the vibration is above the Danger Line, I would recommend bracing (even temporary) be done immediately.

When you add bracing, do you change the stiffness? What’s your comment on changing the damping?

Bracing changes the stiffness of the SBC and increases the MNF. Damping-type braces add very little stiffness but a lot of damping. Damping is inversely related to vibration at resonance.

|

| Tuned mass dampers can eliminate vibrations for fixed-frequency problems |

What is your view on using mass dampers for SBC?

Tuned mass dampers (or vibration absorbers) are very effective at eliminating vibrations for fixed-frequency problems (eg, fixed-speed machinery).

Because they move resonance and don't eliminate it, they are less effective on vibrations in systems with broad-band energy (eg, flow-induced turbulence) or variable speed machinery. Damped vibration absorbers can be used in those cases because the new MNFs have a much lower vibration response. We have used (damped) tuned mass dampers on SBCs for particular cases where bracing alone has not provided the required improvement.

In what condition we can use bolted small-bore supports for orifice tubing, especially to avoid direct welding on mother pipe?

Bolted supports can work very well, particularly at lower frequencies (<100Hz) providing the support itself is much stiffer than the tubing.

When can I specify a damper support? Do I need to check the stress analysis?

Typically, a damper support can be used adjacent to piping with high vibration. If the damper support is replacing a similar hold-down clamp, it should not affect the piping stress analysis (PSA) significantly, however, a PSA engineer should be consulted.

When the vibration is shell mode vibration, what is the best way to support the SBC?

Using a repad or a full encirclement wrap, with gussets, is usually the best solution. Reducing the shell mode vibration should also be attempted.

Could a full encirclement pad reduce vibration?

Full encirclement pads are more useful to help lower pipe shell vibrations, however, they can be difficult to install properly to avoid relative movement between the pipe and the pad. They are not very effective to raise the natural frequency of SBC bending modes.

Could a rubber pad be helpful inside the support around the SBC?

Neoprene is useful to add damping, however, it also reduces stiffness. We recommend 1/8" thick, if used. A pad made of damping material is much more effective.

- Resonance/MNF

If you know that certain compressor speeds cause vibrations that you know would cause damage, and it would be hard to avoid that, would it be feasible to just "speed past" that undesirable range?

Yes, you can move quickly through resonance and operate at a higher speed.

|

| Read more about plunger pump pulsation |

How would you avoid resonance for very slow speed recip pump, in this case, 2.3hz to 6.9Hz?

In most cases, avoiding the plunger passing frequency by 20% is enough. But in some cases, systems are so flexible that non-resonant vibration can be over guideline. It is difficult to identify these systems at the design stage without doing a forced response analysis and actually predict vibrations of the piping and SBC near the recip pump.

- Other

What is the recommended solution for high-frequency vibration on small-bore connection (150 Hz and above)?

Bracing, gussets, repads, full encirclement wraps, etc can be used to reduce high-frequency vibration.

Is PWHT really helpful for to reduce or prevent SBC vibration?

PWHT does help reduce the likelihood of cracking, especially in corrosive or hydrogen environments.

If the small-bore accessory is vibrating in phase with the mainline but is over 1 in/seg pk, but the mainline is 0.6 in/seg pk do you still want to fix the vibration on the small-bore accessory?

Relative vibration tends to cause stress, therefore, that measurement is what we base recommendations on.

5 Strategy and process

In the reciprocating compressor packages, some consultants do not object on putting the small-bore connections for pressure transmitters on the bottles while others do not recommend installing any instrumentation on the bottles. What's your take on this?

We do not recommend any SBCs on pulsation bottles. However, it is possible to have small low-profile SBCs on bottles and not have problems. If flanged connections are required, we would recommend they be gusseted.

Veridian – some evaluation of failure is subjective. How does Wood propose to ensure that a subjective evaluation is applied consistently?

Veridian and the Energy Institute method strive to be as objective as possible; the SBC parameters used in Veridian (and as provided in the EI Guidelines) attempt to remove as much of the subjectivity associated with the SBC assessment as possible.

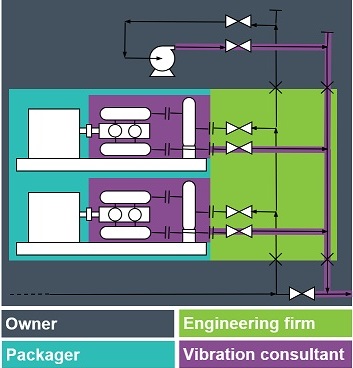

|

| Pulsations and thermal growth cross boundaries of responsibility |

Shouldn't the EPC Contractor do a stress analysis and address all vibration issues?

In many cases, while static piping stress is addressed (eg, using Caesar II vs ASME B31.3), the dynamic piping stress is overlooked. Unless the report contains natural frequencies or vibration amplitudes, then a dynamic piping stress analysis was likely not done.

Supposing we have an EPC contract, does Wood take the risk of the design? Eg, if there is a vibration failure in the auxiliary piping (non-process) or piping complying with guidelines, who is responsible for that design? The engineering consultant or the owner that accepted the use of these guidelines?

Using the Energy Institute guidelines helps both Wood and the owner lower the risk associated with a design. We have seen examples where the owner has stipulated that vibration should be considered in the design, but it was not adequately addressed by the EPC contractor – this led to an insurance claim by the owner). Properly applying the EI Guidelines helps avoid this type of issue.

What can be done at the fabrication stage to prevent rework of shop fit SBC and piping? How can the packager reduce their SBC risk when building recip compressor packages

Avoid any SBC on compressor manifold (eg, suction and discharge bottles). Keep SBC as short as possible by using light low-profile valves. If in doubt, use bracing, gussets, or remote mounting.

6 Other

How does operating a centrifugal compressor at lower RPM affect vibrations?

Excitation mechanisms for centrifugal compressors tend to get lower at lower RPM, and therefore vibrations may go down. However, resonance is a significant cause of vibration, and resonance can occur at any RPM.

What are your thoughts on seal welding for threaded connections for vibration?

Seal welding is acceptable as long as no threads remain exposed. Threaded connections should be avoided in vibrating service.

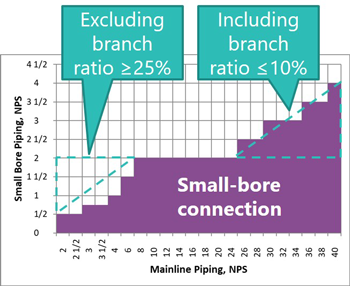

What code is the definition of small-bore piping derived from, especially the figure presented (pipe diameter ratios)?

The NPS 2" and below is from Energy Institute standard. Excluding branch ratio >= 25% is from the GMRC/PRCI standard. Including branch ratio <= 10% is based on Woods experience. The criteria, as described, is very similar to the ISO 10816-8 Annex E, soon to be published.

|

| Small-bore connection definition |

More questions?

Don't hesitate to contact our piping vibration team.

7 More webinars and online calculators

Calculators

Maximum recommended support spacing – support spacing and stiffness for vibratory service

API 618 guideline calculator – how does this industry standard apply to your compressor?

Helmholtz calculator – how effective will your bottle be at reducing acoustical pulsations?

Online bottle sizing – sizing recommendations for pulsation bottles used on reciprocating compressors

Pipe lengths to avoid calculator – ***coming soon***

Related Pages

Integrity Evaluation of Small Bore Connections (Branch Connections) (PDF) • Small-Bore Connections (SBC) Assessment • Webinar: Small bore…Big problem • An Integrated Approach to Manage Vibration Risks • Webinar: Testing the limits •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now