Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Five simple methods to check reciprocating compressor performance

How to spot-check the performance of a reciprocating compressor

By Dr. Bryan Long, principal consultant – vibration dynamics and noise

There are often occasions when it is desirable to spot-check the performance of a reciprocating compressor; just after a rebuild, as part of commissioning or when something seems different.

Here are a few things you can do:

| # |

Method, pros and cons |

Rating | ||

|---|---|---|---|---|

| Quantification of difference in throughput | Diagnostic insight | Ease of use | ||

| 1 | Compare measured flow with that predicted by OEM sizing (or other) software. This is easy to do once a model has been created. Creating the model is not difficult but requires accurate load step numbers (clearances). |

|||

| 2 | Compare inter-stage pressures with software model predictions |

|||

| 3 |

For cylinders on the same stage, compare discharge temperatures. |

|||

| 4 |

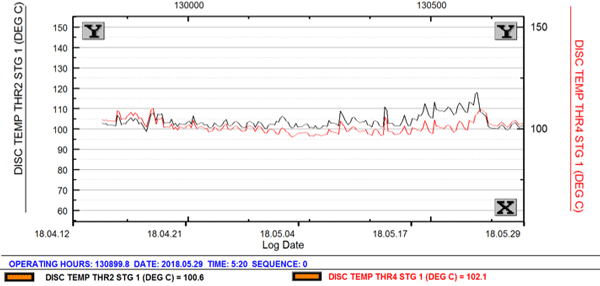

Check for hot valves by comparing equivalent valve cap temperatures |

|||

| 5 |

Calculate the capacity of each stage separately based on observed pressures and suction temperatures and look for significant discrepancy. A model is not required but best to set up an Excel calculation (which requires gas properties). If there is a significant difference, the lower value is the more accurate result, and the other stage has a problem. |

|||

| 6 |

Detailed analysis of pressure-volume curves along with ultrasonic patterns. Well, this is not so simple; included here for comparison.

|

|||

Examples

|

|

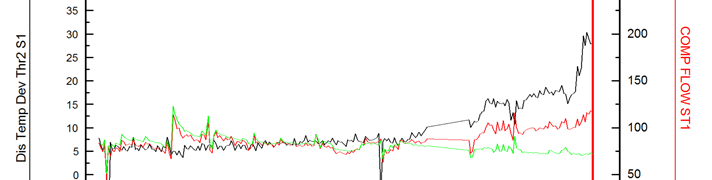

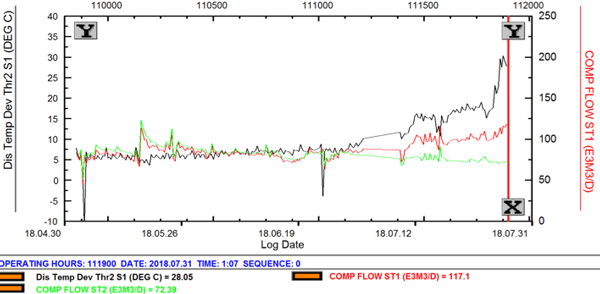

The discharge temperature of a cylinder with a valve leak (black curve) increased, compared to another cylinder on the same stage (red), until a repair was made. |

|

|

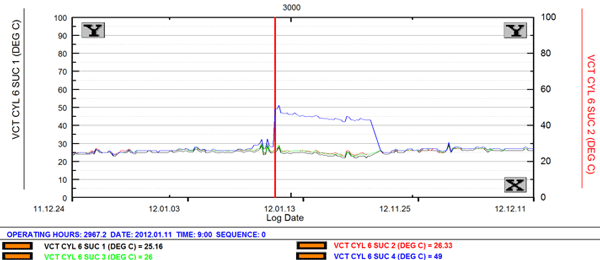

Suction valve cap temperatures show one significantly higher reading, indicating a leak. |

|

|

Calculated capacity of stage 1 increases relative to stage 2 as a leak develops. The leak is verified by the rising discharge temperature deviation (black curve). |

Related Pages

Performance Assessment (Thermodynamic) • Machinery Condition and Performance Monitoring • Condition Monitoring and Remote Vibration Analysis •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now