Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Pulsation analysis – ask the expert

Q&A from our pulsation analysis webinar

The answers below were given in the context of the webinar and do not address all aspects of the issues discussed.

For more comprehensive information or application support, we strongly encourage you to contact our experts directly.

Contents [ hide ]

- 1 Videos

- 2 Calculating and analyzing pulsation forces

- Online calculators

- Pulsation factors

- Guidelines

- Pipe lengths to avoid

- Resonance

- Elbows

- 3 Pulsation control methods

- Bottles/resonators

- Orifice plates

- 4 Vibration and piping

- Supports and clamping

- Small-bore connections

- Reducers

- 5 Project management

- 6 Other

- Tips and conclusions

- Reciprocating pump pulsation

- Screw compressor pulsation

- Liquid ring compressor pulsation

- 7 Support

1 Videos

Webinar recordings

Pulsation videos shown in webinar:

2 Calculating and analyzing pulsation forces

Online calculators

API 618 guideline calculator – how does this industry standard apply to your compressor?

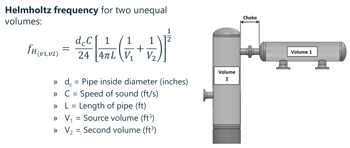

Helmholtz calculator – how effective will your bottle be at reducing acoustical pulsations?

Maximum recommended support spacing – support spacing and stiffness for vibratory service

Online bottle sizing – sizing recommendations for pulsation bottles used on reciprocating compressors

Pipe lengths to avoid calculator – ***coming soon***

Pulsation factors

Should pulsation forces be co-related to structural or support design?

If a system has reasonable pulsation control, pulsation shaking forces will typically be an order of magnitude lower than forces caused by thermal growth and pipe weight. As a result, forces due to piping stress will typically dictate support design.

Are pulsations and pulsation forces related to density?

Yes, density contributes to pulsation amplitudes.

Is there a flow velocity or a pressure level below which resonance is not normally a concern?

Resonance depends on the speed of sound and system geometry. Pressure doesn't directly impact whether resonance will occur. Flow rates and pressures will impact damping, so to that degree, it influences pulsation amplitudes.

How are variable valve unloaders (HydroCOMs) considered in the acoustic analysis?

HydroCOMs regulate capacity by delaying the closing of the suction compressor valves. From a pulsation standpoint, what is important is the profile of the pulsation source strength at the valve – which is significantly different than traditional methods of capacity control (eg, head-end variable-volume pockets). Once the profile is calculated, a pulsation simulation can be performed like for any other type of capacity control.

See this paper for additional information: Acoustical modeling of reciprocating compressors with stepless valve unloaders

|

|

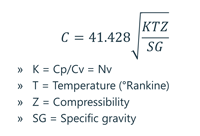

| Speed of sound in gas |

What determines the speed of sound for the gas?

The speed of sound of the gas in the pipe is a function of gas properties (specific gravity, compressibility, etc) and pressure and temperature.

Is the speed of sound impacted by the material of the piping?

For gas systems, the size and material of the piping will not impact the speed of sound of the gas in the piping. For liquid systems, the size and material of the piping will impact the speed of sound of the liquid.

Will simply making the piping natural frequency 2.4 times of compressor solve the problem?

Making the piping natural frequencies above 2.4 times compressor speed will go a long way to mitigating vibration from a mechanical point of view, but you still want to make sure pulsations are well controlled.

Guidelines

You stated the charts represent shaking force violations. How are you defining them ie, what standard or guideline do you use?

Forces are defined by pulsation pressure acting on a cross-sectional area. There are a couple of different guidelines commonly used in industry.

In the presentation, we looked at bottle force guideline. API has a bottle force guideline, as well we VDN has our own guideline based on many decades of doing this type of work. For bottles it is 1000 lb pk-pk for the first couple of orders of run speed, then declines with increasing frequency.

Is API 688 a good guideline for pulsation design?

RP 688 (Recommended Practice document, not a standard yet) tends to be more of a technical educational package rather than a guideline. It provides guidance on the application of pulsation and vibration control requirements found in the API purchasing specifications for positive displacement machinery. The fundamentals of pulsation and piping system analysis are presented in Part 1. Part 2 deals specifically with reciprocating compressors and provides commentary regarding each paragraph of Section 7.9 of Std 618, 5th Edition.

Pipe lengths to avoid

Does pipe geometry (diameter, thickness) affect the response when calculating piping lengths to avoid?

For gas systems, the length of piping has the biggest impact. The diameter of pipe does have a small impact to the extent that there acoustic end effects that come into play at tees and nozzles on vessels.

Annexure N of API 618 describes the pipe length to avoid. Is this the same what you have explained?

Correct, the same basic formula is used in our presentation

What is the relationship between the two volumes?

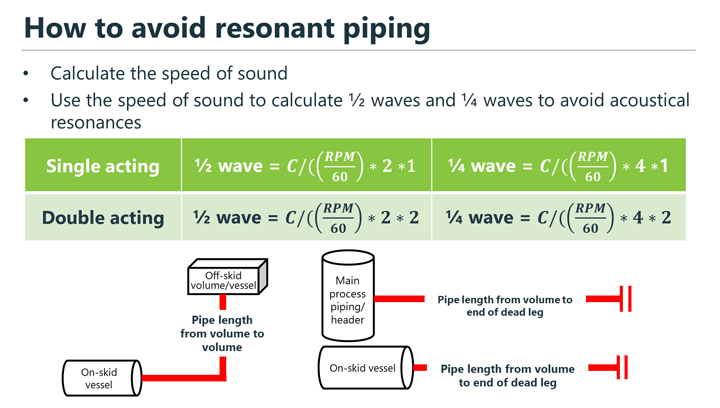

In terms of pipe lengths to avoid, large volumes tend to force pulsation levels to a minimum. Therefore, half wave (and multiples thereof) resonances can set up between volumes.

Are the piping lengths to avoid just the straight lengths vs including equivalent lengths for fittings?

The length of concern is the acoustical length, so straight length plus fittings.

How do you calculate the pipe length to avoid if you have both single acting (SA) and double acting (DA) operation?

If you have multiple loading scenarios (eg, DA and SA) you would need to avoid lengths for both.

|

|

| How to avoid resonant piping – single-acting and double-acting conditions |

Do we have to avoid multiples of this length?

The most important lenghts to avoid are the first fundamentals. However, sometimes it is useful to avoid integer multiples of 1/2 waves and odd multiples of 1/4 waves.

What lengths should be used to calculate the resonance frequencies in a more complex pipework system?

For more complex piping systems a pulsation study should be conducted.

Resonance

What margin between resonance and calculated frequency is considered acceptable?

Typically, between 10% and 20% separation is acceptable.

Elbows

Would using long radius elbow vs short radius elbow affect pulsation?

The difference isn't significant unless you get into very large pipe sizes.

3 Pulsation control methods

Bottles/resonators

Are P.A.N. systems better than pulsation bottles?

P.A.N. systems offer a unique solution for pulsation control, and like any other pulsation control solution has pros and cons.

The intent of a P.A.N. system is to introduce parallel flow paths to cancel out pulsation without introducing pressure drop. The benefit is pulsation control with basically no added pressure drop. The resulting piping system can get complicated and take up space. As well, shaking forces can be high so typically recommend the P.A.N. be routed close to the ground where it can be well supported.

Considering the design of a new system, can pulsation issues be (theoretically) avoided by an increase of volumes and adding supports?

Generally increased volumes (pulsation bottles) will result in lower pulsation levels. Adding supports will not change pulsation but will impact mechanical response. Generally, more supports are better.

More information on small-bore connections is available in our webinar recording: Webinar: Small bore...Big Problem

|

|

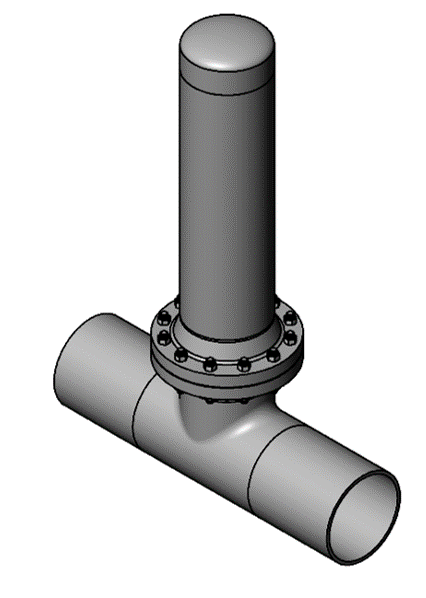

| Helmholtz resonator |

What is the differenece between a resonator and a pulsation dampener?

Both are methods to control pulsation but do not mean the same thing. A pulsation dampener typically refers to a bottle or volume attached to the compressor cylinder, which the gas flows through. A resonator is typically a length of pipe, and/or volume that tees off the main piping to create a side branch (no mean flow through the side branch).

Are Helmholtz resonators used to attenuate narrowband pulsations or a wider band of pulsation energy (say several harmonics)?

Helmholtz resonators (side branch devices) are really only good to attenuate one frequency, not a wide band of pulsation. Helmholtz resonators are sometimes referred to as side branch absorbers.

In some of your examples, the resonator frequency was set below the running speed harmonics. What type of resonator is this?

The term "Helmholtz" has been used in two different scenarios, one case being the Helmholtz resonator described above, ie, a length of pipe and/or volume branched off the main line.

The other case was in the context of a volume-choke-volume arrangement which constitutes a low-pass filter that attenuates a wide range of frequencies. For low-pass filters, the Helmholtz frequency is set below the range of frequencies of concern.

| How to calculate the Helmholtz frequency for two unequal volumes |

Do you have recommendations for using boot legs (liquid drains) on suction bottles for reciprocating compressors?

We do not have any specific recommendations for integral pulsation bottle/liquid separators.

It will be important to include the boot leg in both the pulsation and mechanical studies.

Orifice plates

What range of orifice sizes do you recommend?

Typically recommend between 0.4 - 0.7 Beta Ratio. If you go below 0.4 Beta Ratio orifice plate near the compressor cylinder can result in rod load issues or very high pressure drop. "Beta Ratio" of the orifice - divide the ID of the orifice by ID of the downstream pipe to get Beta Ratio.

Is location important when using orifice plates for pulsation control?

Yes, orifice plates will be more or less effective in controlling pulsation based on location. Orifice plates are most effective in reducing pulsation when they are located where pulsations are minimum (and volume velocities are maximum). Pulsations are typically low at entrance and exits to large volumes.

If an orifice is installed between volume bottle and compressor cylinder, can it be moved to the piping system?

Orifice plates installed between the volume bottle and compressor cylinder will result in different pulsation control (eg, reduce different frequencies of pulsation by different amounts) than if the same size orifice plate was installed in the piping.

4 Vibration and piping

Supports and clamping

Are there any specific pipe support designs to control pulsations?

Supports don't control pulsation but do affect the mechanical response/vibration. Supports needs to be stiff enough to avoid resonance.

See our support spacing calculator for a tool to define support spacing versus pipe size.

When designing off-skid piping, should the piping be designed to be clamped to the steel and not supported by shoes?

It comes down to each individual company specification. Ideally, if you can clamp directly to the steel that is the best. If you have to have shoes (eg, for insulated lines) hold-down type clamps can be incorporated into the shoe design. The shoes can have Teflon liners and/or slotted holes to allow for thermal growth.

Small-bore connections

In some cases, small-bore connections (SBC), such as threaded connections for pressure transmitters or temperature transmitters, cannot be avoided. What are the recommendations in that case?

If you cannot avoid small-bore connections, there are good practices (orientation, layout, reduce lengths, etc) that can be followed to minimize vibration. You can also use studding outlets to reduce the length of the item.

Reducers

Should reducers be avoided upstream or downstream of cooler nozzles or both?

Reducers can be used upstream or downstream of cooler nozzles. They typically will NOT have a big impact on pulsation. From a piping stress (thermal analysis) point of view, reducers have a high stress intensification factor, so they will have an impact on supporting requirements.

5 Project management

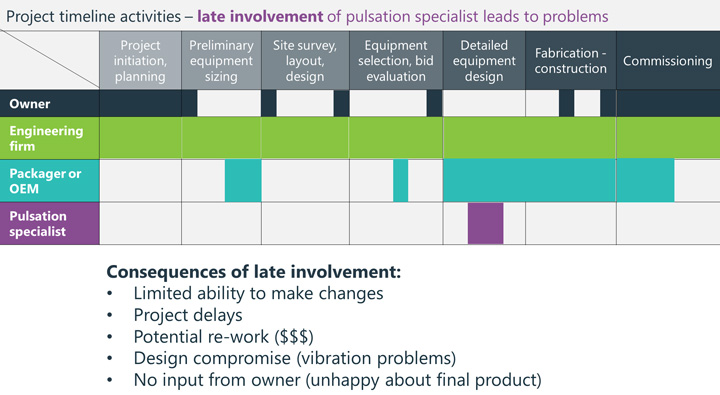

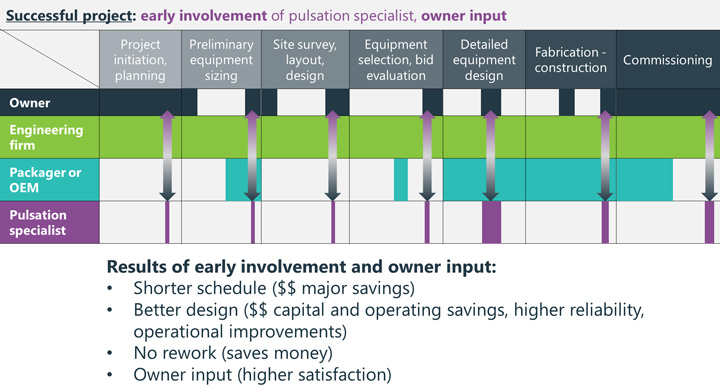

During the EPC phase technical bid evaluation preparation, what data shall be verified from vendors to avoid pulsation? When should you get a vibration/pulsation consultant involved?

A vibration consultant should be involved as early in the process as possible. Once the compressor performance is defined, there are only few options left to control pulsation.

- Pipe lengths to avoid can be calculated as demonstrated in the webinar.

- Pipe support spacing can be defined – see this tool on our website:Pipe support spacing calculator

- The recommended level of pulsation study can be defined – see our vibration risk rating assessment chart (Excel)

Does a pulsation analysis usually include checking resonance against piping natural frequencies?

Strictly speaking, an acoustical analysis considers pulsation resonance. When we do studies, we have options to do acoustical only or add mechanical analysis and forced response (as per API 618).

|

|

|

| When should you get a pulsation consultant involved? |

6 Other

Tips and conclusions

Tips to avoid pulsation problems in reciprocating compressor piping systems:

- Think about the layout from a pulsation point of view right from the start of the design process

- Get pulsation specialists involved early in the design process

- Pipe lengths are important in reciprocating compressor service

- Leave room for pulsation control

- Initial project costs vs a lifetime of high vibration problems and downtime

- Think about thermal growth as well

Reciprocating pump pulsation

Do reciprocating pumps have the same (pulsation) issues as reciprocating compressors?

Yes, reciprocating pumps experience similar issues.

View our free, on-demand pump pulsation webinar for more information:

Webinar: Pump it up, damp it down

Screw compressor pulsation

Could we use screw compressors to avoid pulsation?

Screw compressors also generate pulsation.

View our free, on-demand webinar on how to control screw compressor pulsation for more information:

Webinar: Turning the screw

Liquid ring compressor pulsation

Do liquid ring compressors have a significant risk of pulsation?

Yes, ring compressors also generate pulsation and are susceptible to similar vibration issues.

Contact us for more information and support to avoid ring compressor pulsation.

7 Support

For more information or to get support for your project contact our dedicated pulsation analysis team

Related Pages

Pulsation & Mechanical Analysis: Reciprocating Compressor • Webinar – Feeling the pulse • Training courses and webinars • Videos and Animations • Pulsation & Vibration Control for Small Reciprocating Compressors (PDF) • Pulsations in Suction Piping (Reciprocating Pump) (Video) • Optimizing the Pulsation Control Solution (PDF) • Important Differences in Pulsation Software •

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now