Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Fuel Gas Compressor Piping Transient Analysis

Evaluate Transient Flow at Gas Turbine Inlet

Reciprocating compressors are often used for fuel gas booster applications, feeding one or more gas turbines. Gas turbine manufacturers (OEMs) have strict requirements for flow and pressure variations in the fuel gas supply.

This analysis will assess these transient conditions and provide recommendations to modify the piping system if required. The evaluation includes the piping system between the discharge of the fuel gas compressor to the inlet of the gas turbines.

1_cropped.jpg) |

2_cropped.jpg) |

||

| Field testing the pulsation and transients in a fuel gas system (Asia). Testing verified the accuracy of Wood’s transient analysis results (fuel gas reciprocating compressor feeding gas turbine). |

|||

1 Scope

The scope of the analysis can include these activities:

- Evaluate the steady state pressure pulsations in the system to ensure design specifications are met.

- Evaluate the transient conditions, and determine if a gas accumulator (buffer tank) is required between the booster compressor and gas turbine to reduce pressure variations.

- Provide sizing of buffer tank if required.

- Evaluate criteria such as mean pressure fluctuation, speed of mean pressure variation, and amplitude of pressure variation.

- Evaluate the transient flow and pressure variation through the piping system during start-up or upset conditions. For example:

- A system has 2 fuel gas booster compressors and 2 gas turbines operating at maximum capacity. Evaluate transient pressure changes if one turbine trips causing subsequent shutdown of one compressor. Assess pressure changes in the piping system based on timing for shutdowns, valve operations, etc., and include the “water hammer” due to the sudden stop of the flow.

- Assess the start-up of new turbines added to an existing gas supply system (feeding other gas turbines).

The computer simulation software used for this analysis is Wood’s MAPAK transient solver. This proprietary non-linear, time domain software is used for simulation and analysis of compressor performance, acoustics, pulsations, and transients.

MAPAK software

Various scenarios are evaluated based on operating assumptions provided by the operator. Variables include in the transient model include:

- Time delay between shutdown of compressor and start-up, and loading of the standby compressor

- Fuel gas compositions, flow rates, and bypass valve operating characteristics

- Compressor performance characteristics and volume in the piping system

- Operating pressures and maximum rate of change in pressures allowed at the gas turbine

- Time delays due to control system

- Pressure drop in the piping system

Our clients for these transient studies include:

- Equipment packagers

- Machinery and equipment OEMs

- Engineering, Procurement, and Construction (EPC)

- Owners and operators for gas turbine facilities

2 Related Services

- Reciprocating Compressor: Pulsation and Mechanical Analysis

- Vibration Inspection Program

- Bottle Sizing Service

- Review and Design Support

- Small-Bore Connection (SBC) Assessment

3 Example Projects

|

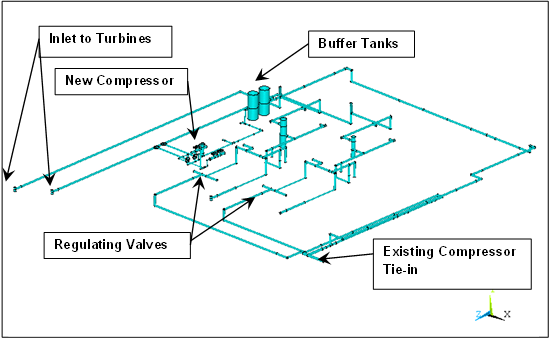

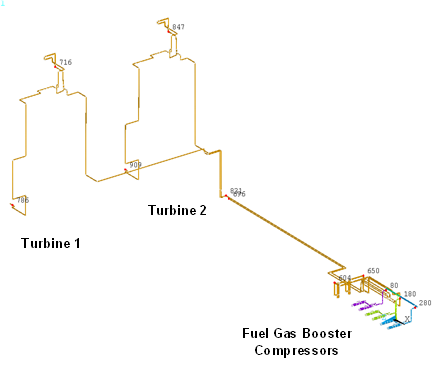

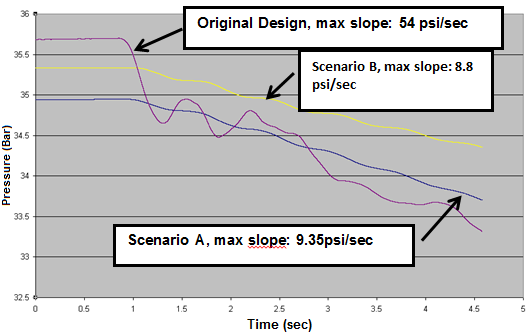

| Acoustic Models of Reciprocating Compressor Discharge to Turbine Inlet |

|

|

|

Transient analysis determines pressure at the turbine inlet for different operating scenarios to ensure gas system meets OEM requirements. |

4 Keywords

- Transient flow at gas turbine

- Fuel gas transient flow

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now